Fatigue Crack Growth and Threshold

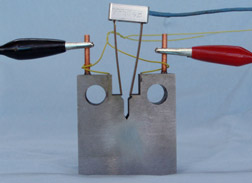

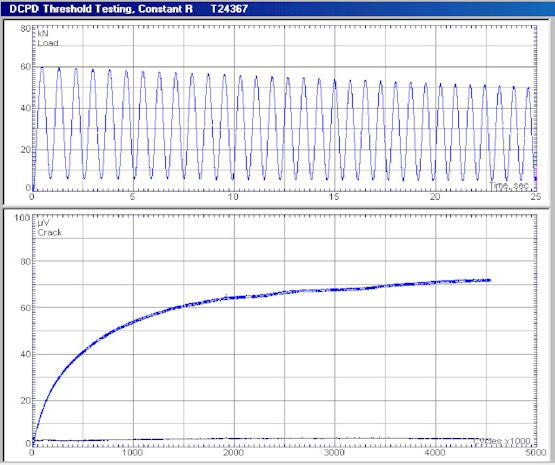

An integrated hardware/software crack growth system provides crack initiation, crack propagation and threshold calculation facilities to meet ASTM E647 and BS6835. Crack lengths are measured using pulsed DCPD technique coupled with specimen crack growth libraries. The technique is extremely sensitive; an increment in crack length of as little as 0.01 mm can be detected. A wide range of specimen types, including compact tension, three point bend, centre cracked tension, and corner cracked specimens can be used. Tests can be carried out under constant load, increasing or decreasing ΔK, or exponentially decreasing Δ K for threshold testing.

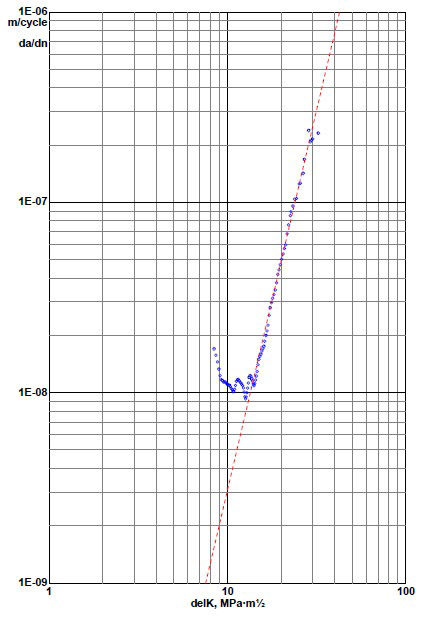

While the test is in progress, voltages are converted into crack lengths, and on screen graphical displays are provided. Raw voltages and number of cycles, peak and trough load readings, and temperature measurements are stored for post-test analysis. A test is terminated either when a target crack length is achieved, or the crack no longer grows, or the rate of crack growth becomes too big. Facilities to create and edit crack growth libraries are provided. The results, including da/dn vs. ΔK, can be displayed, printed or stored as a text file to be used in other applications.